With PRM the charge is also somewhat weaker due to less space to put the charge in -and- as they are also closer together -and- as there is more adjacent area spot-to-spot: they are more susceptible to corruption due to charges 'discharging' or 'neutralizing' each other through the free space. With PRM the head placement has to be more accurate and that inherently means wear issues are more likely cause problems. With PRM the 'spots' are smaller -and- the 'free' space between the 'spots' is also smaller. With Longitudinal Recording the 'spots' on the disc are -physically- larger. So higher RPM drives are built to higher quality standards.Ī secondary thing for older and smaller drives it that they use the Longitudinal Recording Method which is less prone to wear related failures than the newer PRM. As to cost, there is a lower yield on parts coming out of the 'machine shop' and electroplating phases of production due to the tighter tolerances. The firmware also has to be more accurate.

Faster wear from more rotations/time lessens time to out of spec tolerances. The tolerances are tighter for the head to hit the 'right spot' on the disc at a higher RPM so: They use higher quality parts/materials. The drive will not rearrange anything when mersenne twister, random, imaging or any other random data is written.įaster is more stressful on the mechanicals so for faster:

The drive will fix bad sectors on any write but only zeroing improves the speed.

The tools trying to fix one sector at a time can make the bad sector map so convoluted that the drive will give up. If there are too many errors then the operation will halt and you know the disk is bad. The drive will fix and remap all bad sectors including those that are in places the operating system never uses and at the end the drive sorts the bad sector list so the drive works faster. Writing zeros takes the same amount of time as reading the drive but is much more comprehensive. It's a bad technique if you're trying to validate a drive as fully functional. This is a good technique if you are trying to recover data and there's a bad sector interfering.

Seagate seatool software#

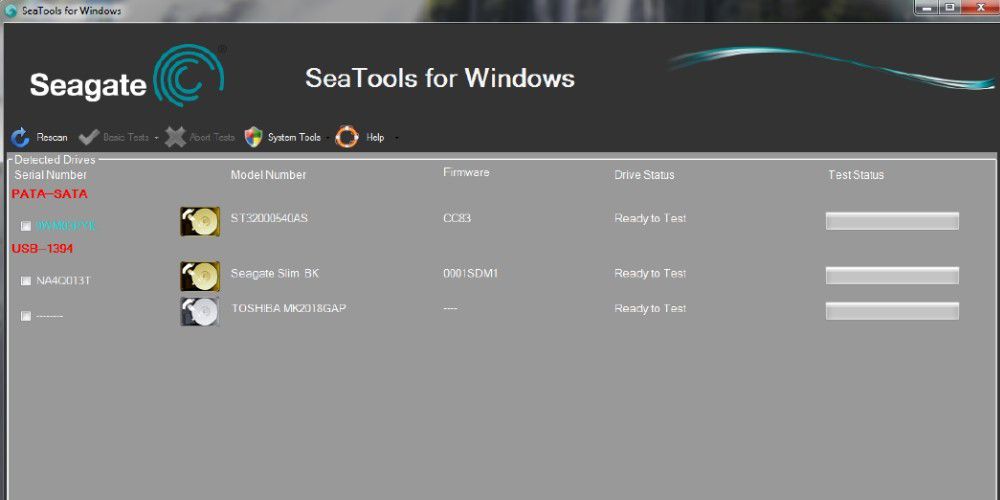

All the software does is to read the whole disk and write zeros to any bad sector it finds. Just write a sector and the firmware does the rest. The firmware on the drive is where the magic happens and no special software is required to make it work. Error correction is not magic performed by the software. There's no reason the software can't run on other brand drives other than to annoy the user. Since there are only 8760 hours in a year isn't that 171 years? I still trust SCSI, median average failure time 1.5 million hours! What's your longevity record for consumer grade IDE and SATA drives. There were three or four newish drives with the "click of death", the heads refusing to park properly.įortunately there was a 750GB with less than 1000 hours, two 250GB drives with no faults, one Seagate 250GB with one error that I corrected, a working 160GB laptop SATA drive, and surprisingly a couple of those skinny Maxtor IDEs which had big hours but no faults. There were several newish drives with I guess bad logic boards as the drive was not detected at all. Some of the drives with unfixable media faults had hours as low as 1800. Most of the drives had POH hours between 500. Since WD and Samsung only evaluate defects, which Seatools does already, why bother?Īt any rate the POH (powered on hours) was very interesting to me. It evaluates any manufacturers drives, and allows error correction on Seagate (and Maxtors made by Seagate) drives. The best tool by far was Seagate's Seatools for DOS. I downloaded all the Drive Tools I could find from Seagate, Western Digital, Samsung, Hitachi and Maxtor.

Seagate seatool plus#

I recently bought a box of 20 plus hard drives, a mixture of IDE and SATA.

0 kommentar(er)

0 kommentar(er)